Exposed: vintage La Favorite "rhums" and sugar...

-

edgarallanpoe

- Quartermaster

- Posts: 99

- Joined: Wed Jun 24, 2015 2:05 pm

- Location: Pittsburgh

Excellent info, and it is truly appreciated.

I had all intentions on buying both Barbancourt rums that are readily available to me. I have always believed that using fine spirits in cocktails makes perfect sense...contrary to most other opinions. I rarely sip my booze....I can, but prefer my alcohol in cocktails. I write this while sipping a margarita made with over 2oz of an extremely expensive Mezcal. Lol

I'll also buy the recommended cachaca, and I'll use it in multiple recipes that call for rum, just to see how it tastes.

You guys are the best and I am grateful for all your help.

I had all intentions on buying both Barbancourt rums that are readily available to me. I have always believed that using fine spirits in cocktails makes perfect sense...contrary to most other opinions. I rarely sip my booze....I can, but prefer my alcohol in cocktails. I write this while sipping a margarita made with over 2oz of an extremely expensive Mezcal. Lol

I'll also buy the recommended cachaca, and I'll use it in multiple recipes that call for rum, just to see how it tastes.

You guys are the best and I am grateful for all your help.

Since the earthquake (and their many lost), they kept producing all their rums like they used to few years back the tragedy, how is that possible ? the actual age on the labels makes no sens anymore to me ; ok, the colums helps a lot there, but how to produce that much aged spirit ? even without official proof, i do believe my source about the subject, but of course that is just my personal opinion, not a 'truth'. Times will tell i guess, i hope.Capn Jimbo wrote:I have not heard this; nor do I believe it. As far as I am concerned, Barbancourt remains a cane juice rum. The only party that has ever denied this - in defense of his two puny Martinique rums - was the Preacher who "heard" that Barbancourt was alleged to use a bit of cane juice syrup (dehydrated cane juice) for the purpose of distilling schedules.cyril wrote:From what i heard, today Barbancourt isn't producing 100% cane juice rum anymore, but a sort of mix cane juice/molasses (how can they produce that much of aged spirit without a big stock since the earthquake, there's no secret). But still a good product tho.

That allegation was, is and remains hearsay, with no citations or real proof of any kind. To the contrary, the Preacher's own site stated that Saint James (Martinique) DID use syrup for this very purpose.

Don't believe it.

earthquake was in 2010 ; Barbancourt changed type of distillation in 1990. they passed from a alambic charentais to a continuous double column (very industrial) who distill at 92%. There's big differences between rums made before 90 and after that change, sadly. their rums are good tho, thats not my point.

Yes St James used cane juice syrup (boiled cane juice) for a while. Books mentioned it for their first millesime (1885), that way they could kill the bacteries and make the rhum 'healthy'. They kept doing it for decades. (and u can see the diffrence between the old 'vesou cuit' and the actual 'pur jus' when you taste those, that is really interesting)

- Capn Jimbo

- Rum Evangelisti and Compleat Idiot

- Posts: 3550

- Joined: Mon Dec 11, 2006 3:53 pm

- Location: Paradise: Fort Lauderdale of course...

- Contact:

Cyril, you are absolutely right...

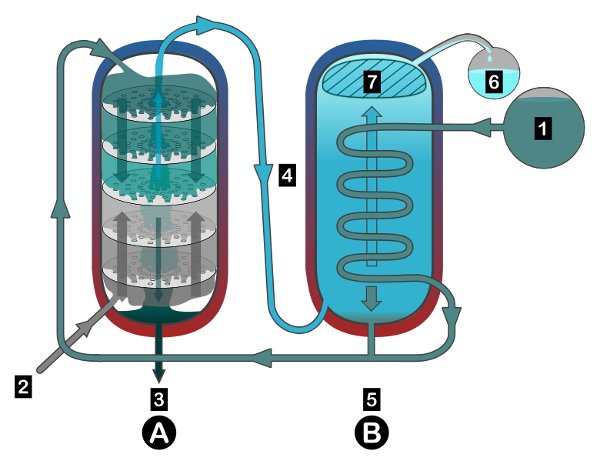

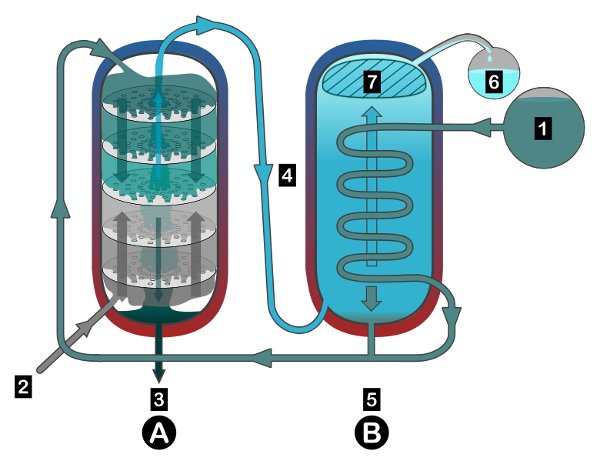

...about the change in stills. I was referring to the Charentais method which intends to produce a more refined spirit. The idea was to capture the heart of hearts. This was originally accomplished using an alembic still designed for this process...

. . . . . . .

Stills of this type were used historically (and even still) in the Cognac region of France, and were brought to Haiti by the Gardiers some 150+ years ago. What you see is an all copper alembic pot whose vaporous output passes through what is a pre-heater in the center, and then passes to a condenser where the final distillate is collected.

The pre-heater was filled with wine, which was then heated to near distillation temperatures - at this point a valve could be opened, feeding the pre-heated wine into the alembic pot. This allowed a sort of semi-continous process, the first goal of this method.

More important and relevent here is the notion of refinement. In the method, only the heart of hearts was collected, while the hearts of 60% were collected, but then added to the pot for a redistillation. Using this method resulted in a purity of about 90%, and the heart of hearts.

Barbancourt did convert to a column-based system (as did Marinique), but NOT to a full-blown, "very industrial" continuous system, but more to one that seems to be of the two-column, historical Coffey method (ie with an analyser, and a rectifier).

In search of purity

This is a good time to reflect on the types of stilling and their relative outputs:

1. Alembic/pot: pot stills are known to produce a comparatively heavy spirit, and at the least require a very slow distillation, or more likely a double (and rarely, a triple) distillation, with the spirit being further refined (higher alcohol) with each pass.

There are schemes that intend to mimic a semi-continuous production (like the Charentais), or to save time by adding "thumpers" in between the pot and the condenser (these perform additional distillations/reflux/refinement).

In terms of purity, the pot method cannot eliminate the capture of some of the nasty heads and tails, the question is how much.

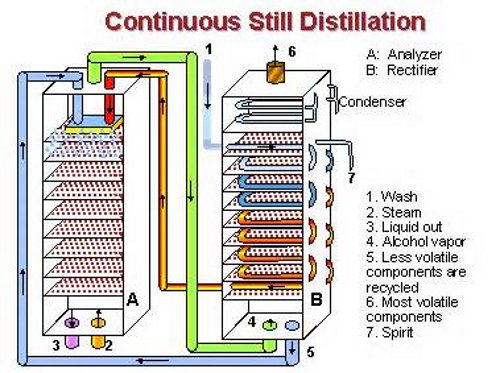

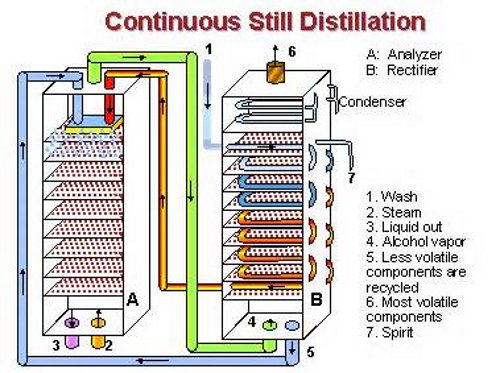

2. Coffey Still: this also is historic and uses two modest columns: the first is the "analyser" where the wash is inserted at the top, while steam rises from the bottom. The wash descends downward, step by step through a series of "bubble plates", and progressively becomes more refined. You might think of the Martiniqean single column stills.

. . . . . . .

The first output is around 60% then passes to the second column, the "rectifier" for additional refining, The rectifier has no plates, but in many ways duplicated the pre-heating of the Charentais, while further refining the output, closer to 90%. Coffey stills have been compared to a series of pot stills (the plates), with each further refining the distillate.

Whereas the Charentais was semi-continuous, the old Coffey's made it possible to just keep distilling. The output is controlled by the number of plates, is usually lighter (but doesn't have to be), but in no way should be confused with "very industrial" output of the huge and truly industrial multi-column factories (which often have up to five huge columns, pumping out near vodka at close to 95%.

Coffey output: still rich, more refined, lighter.

3. Industrial Multi-Column stills: you know these well. These are huge and literal factories. The multiple columns (almost always more than two, even five) are immense and are designed with one objective to produce alcohol of maximum purity, and to remove the congeners (and taste) to product near vodka, vodka and grain neutral spirits.

. . . . . . .

There is no pretense of trying to capture and retain the essence or character of the spirit (as is done with pot or simple Coffey stills), but to run the wash as fast as possible, and to capture as much pure or nearly pure alcohol as possible.

These huge operations - which look more like a chemical plant - can clearly be called "very industrial". They have a single focus: nearly pure and tasteless alcohol from 94-95%.

Flat Ass Bottom Line

While it is possible to to produce VERY highly refined spirits from a modified pot (like many of the Carls built for craft distillers) or Coffey; it is fair to say that the pots, modified pots and Coffeys are often used to produce tasty spirits of 90% or less, including bourbon, whiskey, and rum.

None of these earn the "very industrial" designation that is better applied to the huge, multi-column and truly industrial factories. While tasty spirits can be produced from around 70 to 90%, there is no comparison whatever with those produced at or near 95%.

Sadly, much rum IS produced at close to 94%, but which is then tricked up with sugar and all the other additives we know of. It HAS to be. For comparison, the judicious use of a single or Coffey column (think Seales or Barbancourt) can produce a very consistent and tasty product that requires no alteration.

*******

Bunnyhug's visit to Barbancourt (a few errors):

http://bunnyhugs.org/2008/10/25/rhum-ba ... ery-visit/

Wiki on Coffey Still:

https://en.wikipedia.org/wiki/Column_still

...about the change in stills. I was referring to the Charentais method which intends to produce a more refined spirit. The idea was to capture the heart of hearts. This was originally accomplished using an alembic still designed for this process...

. . . . . . .

Stills of this type were used historically (and even still) in the Cognac region of France, and were brought to Haiti by the Gardiers some 150+ years ago. What you see is an all copper alembic pot whose vaporous output passes through what is a pre-heater in the center, and then passes to a condenser where the final distillate is collected.

The pre-heater was filled with wine, which was then heated to near distillation temperatures - at this point a valve could be opened, feeding the pre-heated wine into the alembic pot. This allowed a sort of semi-continous process, the first goal of this method.

More important and relevent here is the notion of refinement. In the method, only the heart of hearts was collected, while the hearts of 60% were collected, but then added to the pot for a redistillation. Using this method resulted in a purity of about 90%, and the heart of hearts.

Barbancourt did convert to a column-based system (as did Marinique), but NOT to a full-blown, "very industrial" continuous system, but more to one that seems to be of the two-column, historical Coffey method (ie with an analyser, and a rectifier).

In search of purity

This is a good time to reflect on the types of stilling and their relative outputs:

1. Alembic/pot: pot stills are known to produce a comparatively heavy spirit, and at the least require a very slow distillation, or more likely a double (and rarely, a triple) distillation, with the spirit being further refined (higher alcohol) with each pass.

There are schemes that intend to mimic a semi-continuous production (like the Charentais), or to save time by adding "thumpers" in between the pot and the condenser (these perform additional distillations/reflux/refinement).

In terms of purity, the pot method cannot eliminate the capture of some of the nasty heads and tails, the question is how much.

2. Coffey Still: this also is historic and uses two modest columns: the first is the "analyser" where the wash is inserted at the top, while steam rises from the bottom. The wash descends downward, step by step through a series of "bubble plates", and progressively becomes more refined. You might think of the Martiniqean single column stills.

. . . . . . .

The first output is around 60% then passes to the second column, the "rectifier" for additional refining, The rectifier has no plates, but in many ways duplicated the pre-heating of the Charentais, while further refining the output, closer to 90%. Coffey stills have been compared to a series of pot stills (the plates), with each further refining the distillate.

Whereas the Charentais was semi-continuous, the old Coffey's made it possible to just keep distilling. The output is controlled by the number of plates, is usually lighter (but doesn't have to be), but in no way should be confused with "very industrial" output of the huge and truly industrial multi-column factories (which often have up to five huge columns, pumping out near vodka at close to 95%.

Coffey output: still rich, more refined, lighter.

3. Industrial Multi-Column stills: you know these well. These are huge and literal factories. The multiple columns (almost always more than two, even five) are immense and are designed with one objective to produce alcohol of maximum purity, and to remove the congeners (and taste) to product near vodka, vodka and grain neutral spirits.

. . . . . . .

There is no pretense of trying to capture and retain the essence or character of the spirit (as is done with pot or simple Coffey stills), but to run the wash as fast as possible, and to capture as much pure or nearly pure alcohol as possible.

These huge operations - which look more like a chemical plant - can clearly be called "very industrial". They have a single focus: nearly pure and tasteless alcohol from 94-95%.

Flat Ass Bottom Line

While it is possible to to produce VERY highly refined spirits from a modified pot (like many of the Carls built for craft distillers) or Coffey; it is fair to say that the pots, modified pots and Coffeys are often used to produce tasty spirits of 90% or less, including bourbon, whiskey, and rum.

None of these earn the "very industrial" designation that is better applied to the huge, multi-column and truly industrial factories. While tasty spirits can be produced from around 70 to 90%, there is no comparison whatever with those produced at or near 95%.

Sadly, much rum IS produced at close to 94%, but which is then tricked up with sugar and all the other additives we know of. It HAS to be. For comparison, the judicious use of a single or Coffey column (think Seales or Barbancourt) can produce a very consistent and tasty product that requires no alteration.

*******

Bunnyhug's visit to Barbancourt (a few errors):

http://bunnyhugs.org/2008/10/25/rhum-ba ... ery-visit/

Wiki on Coffey Still:

https://en.wikipedia.org/wiki/Column_still

- Capn Jimbo

- Rum Evangelisti and Compleat Idiot

- Posts: 3550

- Joined: Mon Dec 11, 2006 3:53 pm

- Location: Paradise: Fort Lauderdale of course...

- Contact:

Coffey Patent Stilling 102...

...howzit work?

. . . . . . .

(Irish Whiskey still, all copper)

. . . . . . .

In the first column (on the left), the "analyzer", steam rises, with the wash inserted at the top, and dripping down, step-by-step through the bubble plates. The more volatile elements rise (to about 60%), and exit via the top.

The second column - to the right - is the "rectifier" . The roughly 60% vapor is inserted, this time at the bottom. Note that the rectifier also acts as a pre-heater ((like the Charentais), with new wash traveling down a snakelike tube, to top of the first column, the analyser. Meanwhile the 60% vapor is now traveling up, rising through a series of compartment, with the heavier, less volatile elements sinking down (to be revaporized).

Ultimately the lightest, most refined vapors make it to the top, which is occupied by a condenser, and the distillate is finally collected.

To be fair, the Coffey acts very much like the Charentais, except that it is fully continuous. The Coffey essentially emulates multiple passes through the alembic pot still of the Charentais set-up. Today, the most common setup for the craft, micro or "artisan" distiller - with money - would be a modified pot with column, or a pot piped to a small single column as best exampled by Carl of Germany (who also makes smaller Coffeys).

There are any number of modifications depending on the intentions of the distiller (many of whom want to be able to produce a wide range of brown and white spirits, the latter for quick sale, the former as the usual pipe dream of producing real aged whiskey or bourbon, someday, somehow.

*******

An excellent description of the Coffey process with illustrations:

http://www.stillcooker.com/patent-still.php

...howzit work?

. . . . . . .

(Irish Whiskey still, all copper)

. . . . . . .

In the first column (on the left), the "analyzer", steam rises, with the wash inserted at the top, and dripping down, step-by-step through the bubble plates. The more volatile elements rise (to about 60%), and exit via the top.

The second column - to the right - is the "rectifier" . The roughly 60% vapor is inserted, this time at the bottom. Note that the rectifier also acts as a pre-heater ((like the Charentais), with new wash traveling down a snakelike tube, to top of the first column, the analyser. Meanwhile the 60% vapor is now traveling up, rising through a series of compartment, with the heavier, less volatile elements sinking down (to be revaporized).

Ultimately the lightest, most refined vapors make it to the top, which is occupied by a condenser, and the distillate is finally collected.

To be fair, the Coffey acts very much like the Charentais, except that it is fully continuous. The Coffey essentially emulates multiple passes through the alembic pot still of the Charentais set-up. Today, the most common setup for the craft, micro or "artisan" distiller - with money - would be a modified pot with column, or a pot piped to a small single column as best exampled by Carl of Germany (who also makes smaller Coffeys).

There are any number of modifications depending on the intentions of the distiller (many of whom want to be able to produce a wide range of brown and white spirits, the latter for quick sale, the former as the usual pipe dream of producing real aged whiskey or bourbon, someday, somehow.

*******

An excellent description of the Coffey process with illustrations:

http://www.stillcooker.com/patent-still.php

- Capn Jimbo

- Rum Evangelisti and Compleat Idiot

- Posts: 3550

- Joined: Mon Dec 11, 2006 3:53 pm

- Location: Paradise: Fort Lauderdale of course...

- Contact:

A partial of one column...

It is still unclear as to Barbancourt's exact set-up. Pictures of the still are VERY hard to find, which is why you're here, of course...

. . . . . . .

http://bunnyhugs.org/wp-content/uploads ... 0001_1.jpg

This modest copper column replaced a stainless Coffey (following), which was quickly replaced as copper is far superior to stainless (which does not remover sulfur/oxide)

It seems that the earliest stills (early 1800's) were indeed the Charentais type (all copper, classic alembic), designed for semi-continuous process with a third preheating chamber used to charge the alembic. The spirit was a double distillation to obtain just the heart of hearts, with the remainder of the hearts being redistilled.

Later at least one column was added, with a second distillation with an alembic/pot. It is alleged that a stainless Coffey was tried for a short time, but rejected and replaced by an all copper column (pictured above).

. . . . . . .

http://www.barbancourt.net/images/commo ... lation.png

This pic shows a rather modest stainless Coffey patent still (with the rectifier on the left). This still was replaced by an all copper column.

Dave Russell (who travels the islands and visits the distilleries as possible) claims that the first column distillation is to 70%, with the second to 90%. These are the most reported percentages.

As far as the myth that Barbancourt was forced by the most recent earthquake to somehow use molasses is false. Although the total losses were about $4M in equipment, et al, only a few hundred thousand dollars of stocks were lost, a small amount considering that Barbancourt's annual output is about $3M in cane juice rum.

*******

http://www.rumgallery.com/barbancourt-15-year-old.html

http://haitiinnovation.org/en/2007/02/0 ... ian-spirit

It is still unclear as to Barbancourt's exact set-up. Pictures of the still are VERY hard to find, which is why you're here, of course...

. . . . . . .

http://bunnyhugs.org/wp-content/uploads ... 0001_1.jpg

This modest copper column replaced a stainless Coffey (following), which was quickly replaced as copper is far superior to stainless (which does not remover sulfur/oxide)

It seems that the earliest stills (early 1800's) were indeed the Charentais type (all copper, classic alembic), designed for semi-continuous process with a third preheating chamber used to charge the alembic. The spirit was a double distillation to obtain just the heart of hearts, with the remainder of the hearts being redistilled.

Later at least one column was added, with a second distillation with an alembic/pot. It is alleged that a stainless Coffey was tried for a short time, but rejected and replaced by an all copper column (pictured above).

. . . . . . .

http://www.barbancourt.net/images/commo ... lation.png

This pic shows a rather modest stainless Coffey patent still (with the rectifier on the left). This still was replaced by an all copper column.

Dave Russell (who travels the islands and visits the distilleries as possible) claims that the first column distillation is to 70%, with the second to 90%. These are the most reported percentages.

As far as the myth that Barbancourt was forced by the most recent earthquake to somehow use molasses is false. Although the total losses were about $4M in equipment, et al, only a few hundred thousand dollars of stocks were lost, a small amount considering that Barbancourt's annual output is about $3M in cane juice rum.

*******

http://www.rumgallery.com/barbancourt-15-year-old.html

http://haitiinnovation.org/en/2007/02/0 ... ian-spirit

Thanks for the pictures and the technical information, its always useful to read.

im finishing an article (for some french magazine) about Barbancourt Collectors, and contacted some people for accurate informations, and here are some of them :

90's marked the end of the use of the potstill and the end of the double distillation process. they now make rum between 92 and 93% thanks to their double column (its not a creole column and cant stand comparaison to the ones use in the french islands).

Few years ago they extended their distillery with many innox tanks to boil their pure juice and transform it into syrup. syrup is for few years a main composant of their rum.

it does means the rum they are producing since 1990's are quite different from the one produced before that date. tasting samples is the best way to check this, but quite hard to find, of course.

im finishing an article (for some french magazine) about Barbancourt Collectors, and contacted some people for accurate informations, and here are some of them :

90's marked the end of the use of the potstill and the end of the double distillation process. they now make rum between 92 and 93% thanks to their double column (its not a creole column and cant stand comparaison to the ones use in the french islands).

Few years ago they extended their distillery with many innox tanks to boil their pure juice and transform it into syrup. syrup is for few years a main composant of their rum.

it does means the rum they are producing since 1990's are quite different from the one produced before that date. tasting samples is the best way to check this, but quite hard to find, of course.

- Capn Jimbo

- Rum Evangelisti and Compleat Idiot

- Posts: 3550

- Joined: Mon Dec 11, 2006 3:53 pm

- Location: Paradise: Fort Lauderdale of course...

- Contact:

It is my position that Barbancourt uses mostly fresh cane juice, with perhaps some dehydrated juice reserved to fill in the production schedules.

It seems clear to me that Barbancourt uses a smaller patent Coffey still which emulates their earlier use of a column/pot double distillation (which emulated their even earlier us of the Charentais), to about the same percentage (about 90%). A Coffey still should not be confused with industrial column stills. It should also be noted that the AOC cane juice rhums use a single column (up to 5 plates), and which also reserve some dehydrated cane juice.

Barbancourt also ages at lower percentages which require longer aging, and therefore are aged for longer than most AOC's.

I do take issue with the labels which mention only pot stills, regardless of the fact that Coffey stills are known to produce very similar product. I will write Barbancourt (or call their New York rep) regarding this matter...

It seems clear to me that Barbancourt uses a smaller patent Coffey still which emulates their earlier use of a column/pot double distillation (which emulated their even earlier us of the Charentais), to about the same percentage (about 90%). A Coffey still should not be confused with industrial column stills. It should also be noted that the AOC cane juice rhums use a single column (up to 5 plates), and which also reserve some dehydrated cane juice.

Barbancourt also ages at lower percentages which require longer aging, and therefore are aged for longer than most AOC's.

I do take issue with the labels which mention only pot stills, regardless of the fact that Coffey stills are known to produce very similar product. I will write Barbancourt (or call their New York rep) regarding this matter...

Well, its not my personal positions, its facts actually, and it comes from the Gardère family, not me.

i was still believeing in the double distillation process when i red Dave Broom's book RUM (from 2003 if i remember right), but the thing is, that was old informations and not updated ones. like almost everything you read about Barbancourt unfortunately. Their fermentation is not 3 days anymore, thats another example. they used a natural fermentation back in the days, they do not do it anymore, of course.

im not saying this against Barbancourt, this is one of the first brand i ever loved, but for me its a shadow today, and im sad about it.

i hope u'll have the same answers from the brand's representants.

i was still believeing in the double distillation process when i red Dave Broom's book RUM (from 2003 if i remember right), but the thing is, that was old informations and not updated ones. like almost everything you read about Barbancourt unfortunately. Their fermentation is not 3 days anymore, thats another example. they used a natural fermentation back in the days, they do not do it anymore, of course.

im not saying this against Barbancourt, this is one of the first brand i ever loved, but for me its a shadow today, and im sad about it.

i hope u'll have the same answers from the brand's representants.